ABSTRACT

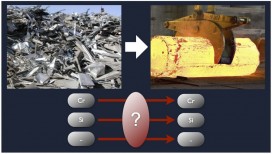

The paper illustrates the use of advanced software for the design of the metallic charge and slag in the EAF in order to optimize the use of materials reducing direct costs, hidden costs, environmental impact.

INTRODUCTION

In the past few years we have been able to monitor and check steelmaking processes in real time, thanks to new technologies.

The checking of slag formation in primary processes according to the type of steel one is to produce has always been subject to often-uncontrolled customary practices.

We wish to draw attention to an example to which we have applied new software tools that have allowed us to achieve excellent results in terms of financial and investment returns, a reduction in environmental impact and increase in quality.

[ SCARICA BROCHURE ]